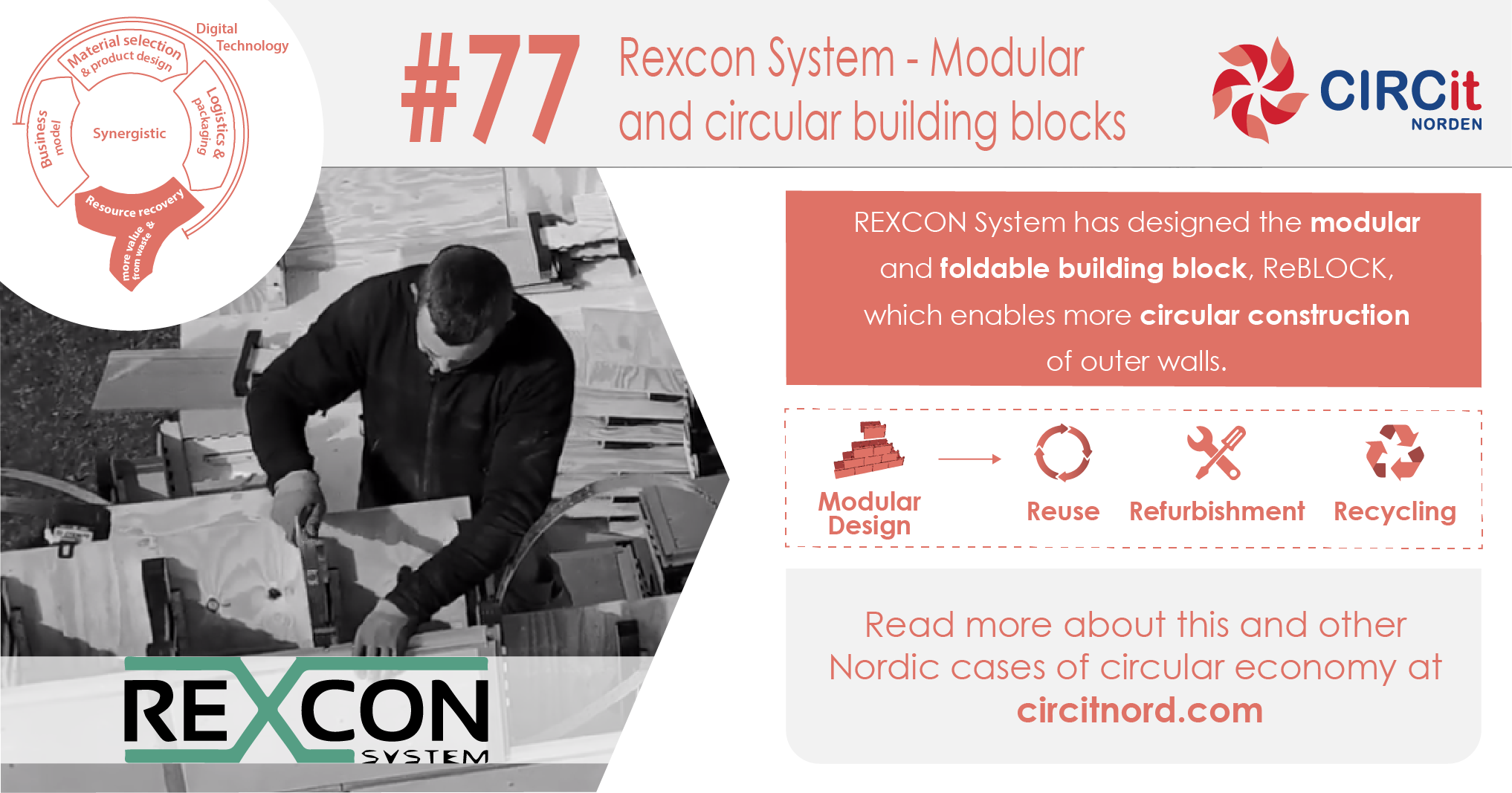

REXCON System has designed the modular and foldable building block, ReBLOCK, which enables more circular construction of outer walls.

The building and construction industry is currently estimated to account for about 39% of the world’s total emissions of greenhouse gas and materials and construction processes alone accounts for about 11%. In Denmark, the industry created about 5 million tonnes of mixed construction waste in 2018. The Danish company REXCON system is working to minimise the impacts from the industry with their modular and foldable building block, ReBLOCK, to construct outer walls. The blocks are made mainly from plywood with a galvanised steel profile and a cement bonded particle board, to protect against the outdoor climate. ReBLOCKS are joined mechanically, for which reason they have been designed for multiple disassembly and reassembly. This is beneficial from a circularity perspective, as it enables reuse, refurbishment and recycling of the blocks and materials. The foldability makes the ReBLOCK more efficient in transport – building blocks for a 140 sqm house can fit onto 6 EURO pallets, which is a significant minimisation of resources needed for transport. REXCON system is also working on establishing business models that involve take-back of their product, to further increase the circular potential of the blocks.

Read more about

REXCON system and their ReBLOCK

or hear this podcast from MADE about the system