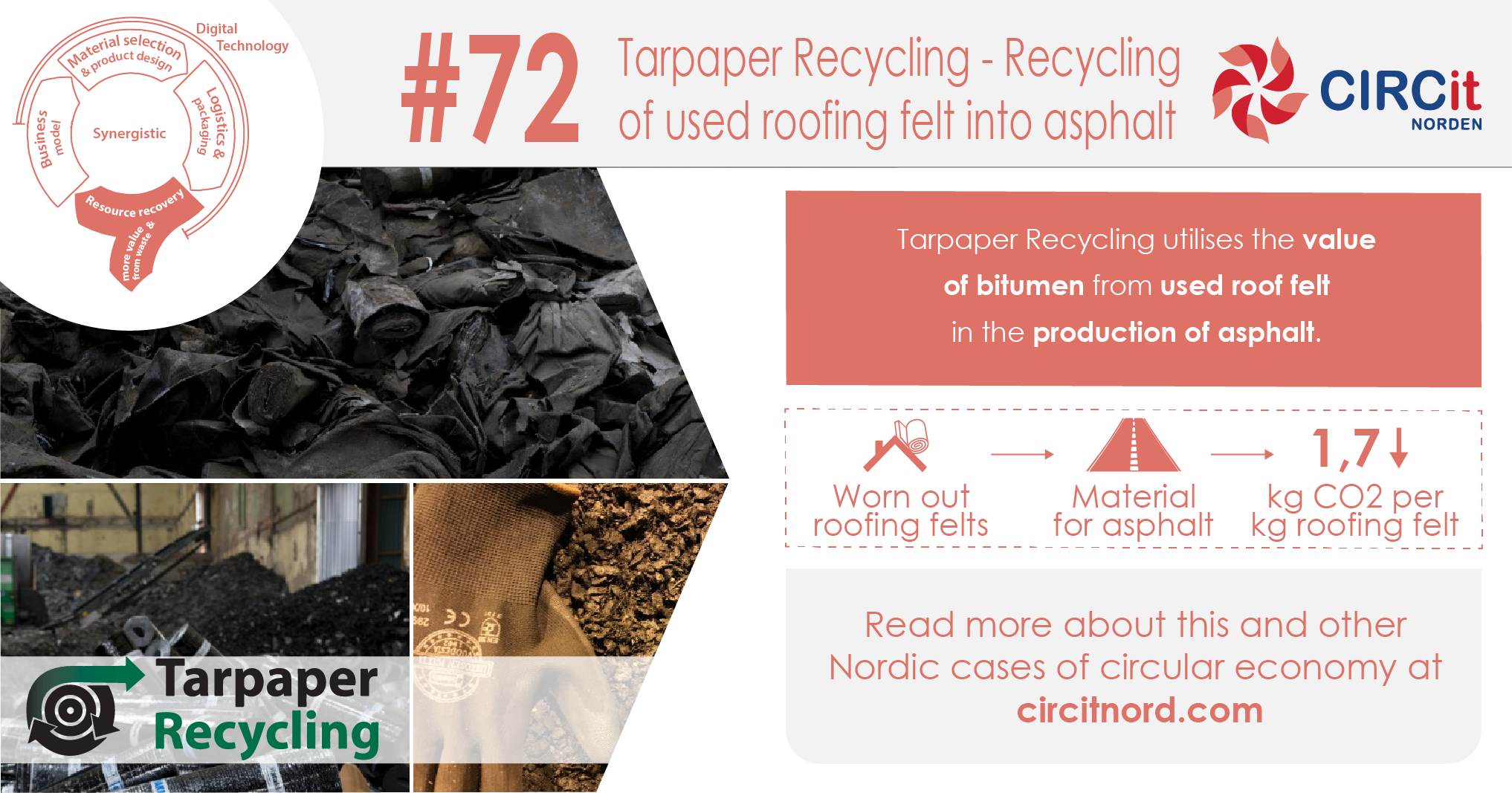

Tarpaper Recycling utilises the value of bitumen from used roof felts in the production of asphalt.

The Danish company Tarpaper Recycling converts worn out roofing felts into a bitumen material to be used in asphalt. The company collects roofing felts in both Denmark, Sweden and Germany or it can be delivered to one of their facilities. At their recycling facilities, they recycle the bitumen (which is a valuable refined oil product) from the felts, using a patented technology. The BitumenMix produced in the recycling process can be added as a fixing agent in the production of new asphalt. About 3% of the total 5% bitumen needed in the asphalt can be replaced with BitumenMix. The worn out roofing felts might otherwise have been disposed of or incinerated in waste facilities. Despite the fact that it derives from waste, Tarpaper Recycling has been CE certified for BitumenMix. A reduction of 1,7 kg CO2 per kg roofing felt waste is recycled – this equals to 60 kg CO2 per ton asphalt produced. By recycling the material instead, both resources and emissions are saved, due to the minimisation of virgin material needed for the asphalt production.

Read more about

Tarpaper Recycling and their utilisation of worn out roofing felts