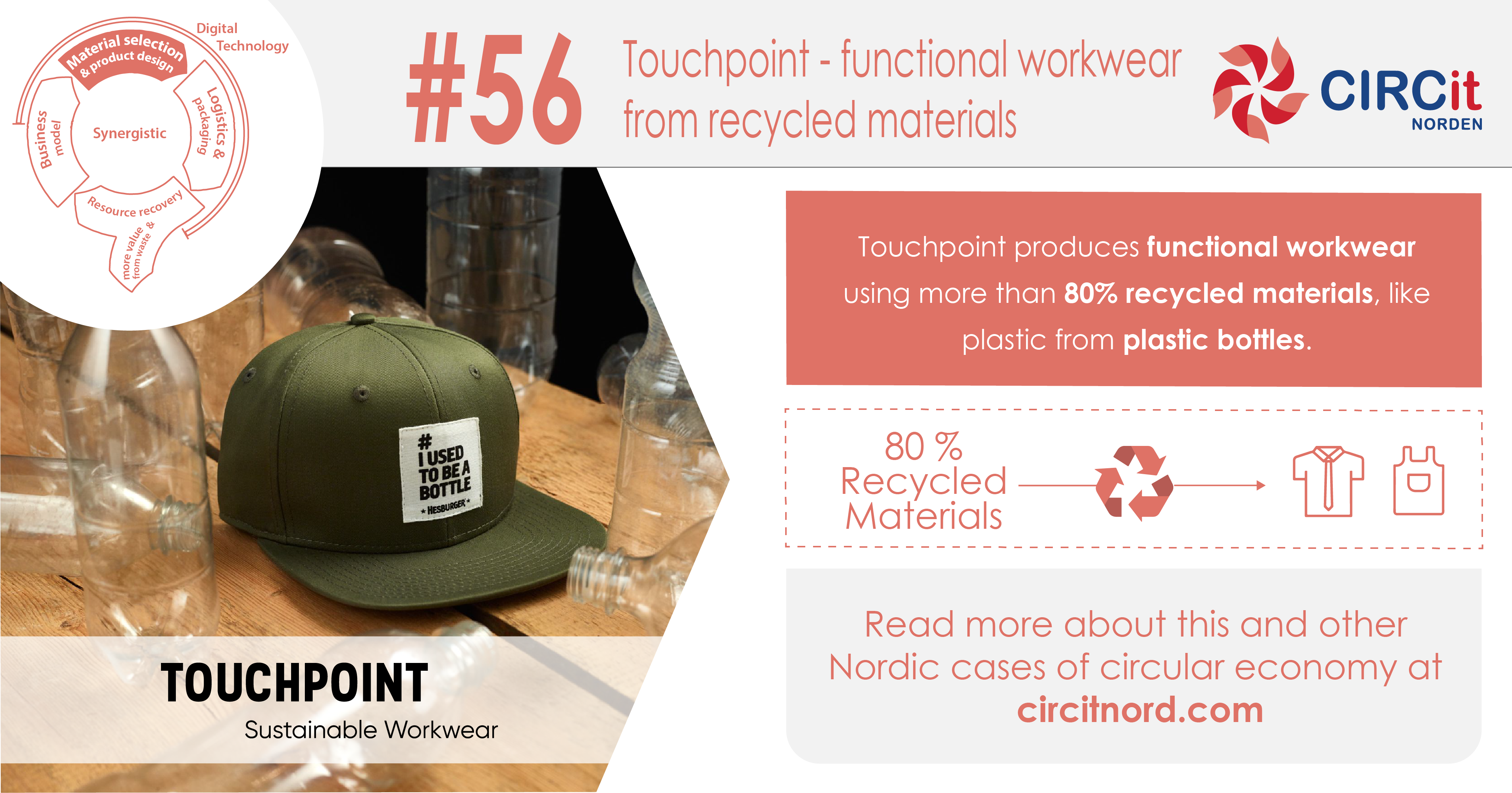

Touchpoint produces functional workwear using more than 80% recycled materials, like plastic from plastic bottles.

Consumption of clothing, footwear and textiles in the EU is the category accounting for the fourth-highest use of primary raw materials. Touchpoint wants to contribute to lowering the use of new resources in the sector. In its design of functional workwear, Touchpoint uses multiple circular product design principles. In its selection of materials, it uses more than 80% recycled materials and collaborates with innovative fabric companies to find high performing, more sustainable materials. One of its suppliers incorporates cutting waste in fabric production. In this process, cutting waste (cotton) is mixed with recycled polyester and spun into new yarn. By using this approach, one saves about 2 700 litres of water per t-shirt, which equals the amount of water used when producing a t-shirt from virgin cotton. The company is also building a closed-loop facility to take care of textile waste. This production facility turns textile waste into new raw material for other industries, for example for the construction industry.

Read more about

touchpoint and its efforts to create circular workwear